Bearings are the backbone of industrial machinery, ensuring seamless operation and supporting the heavy demands of various applications. Choosing the right bearings is essential to maintain efficiency, reduce downtime, and prevent costly repairs. This article delves into the importance of bearings in industrial equipment, the consequences of poor selection, and how Noormsons can be your trusted partner for premium quality bearings.

What Are Bearings and Their Key Role?

Bearings are mechanical components designed to reduce friction between moving parts while supporting loads. They ensure smooth and efficient operation of machinery, enabling industries to achieve their production goals with minimal interruptions. Their key roles include:

- Reducing Friction: Bearings decrease the friction between rotating or sliding parts, enhancing energy efficiency.

- Load Support: They distribute both radial and axial loads evenly, safeguarding other machine components.

- Durability and Longevity: Bearings mitigate wear and tear, prolonging the life of industrial equipment.

- Enhanced Precision: Bearings maintain alignment and precision, which is critical in industries like aerospace and manufacturing.

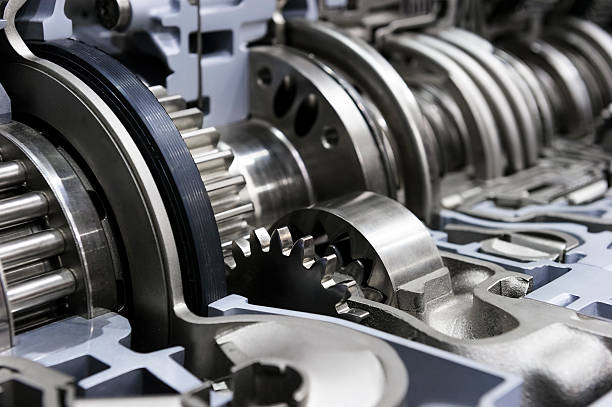

Types of Bearings and Their Applications

Industrial applications demand various types of bearings based on load types, speed, and environmental conditions. Here’s a look at the most common types and their uses:

1. Ball Bearings

- Applications: Electric motors, fans, and conveyors.

- Advantages: High-speed capability and low maintenance needs.

2. Roller Bearings

- Applications: Heavy machinery like crushers and industrial presses.

- Advantages: Ideal for handling heavy radial loads.

3. Thrust Bearings

- Applications: Automotive steering systems and turbines.

- Advantages: Excellent axial load management.

4. Needle Bearings

- Applications: Gearboxes and compressors.

- Advantages: Compact and efficient for high-load applications.

5. Spherical Bearings

- Applications: Misalignment-heavy equipment like conveyors.

- Advantages: Self-aligning properties reduce stress.

Factors to Consider When Selecting Bearings

Choosing the right bearing requires evaluating key factors to match the machinery’s demands:

1. Load Capacity

Bearings should match the radial and axial load requirements of the application. For example, roller bearings are best for high radial loads, while thrust bearings manage axial loads effectively.

2. Speed Ratings

High-speed applications require bearings with low friction and superior heat dissipation.

3. Operating Environment

Consider exposure to moisture, dust, chemicals, and extreme temperatures. Sealed or shielded bearings are ideal for harsh environments.

4. Material Durability

Steel is common, but advanced materials like ceramics offer better performance in specific conditions.

5. Lubrication Needs

Bearings must be adequately lubricated to reduce wear and enhance performance.

The Risks of Using Incorrect Bearings

Failing to choose the right bearings can lead to numerous problems, including:

- Frequent Downtime: Equipment may break down more often, disrupting operations.

- Costly Repairs: Increased wear leads to higher maintenance and replacement costs.

- Reduced Efficiency: The wrong bearings can cause overheating and energy inefficiency.

- Safety Hazards: Malfunctioning bearings can lead to accidents, risking employee safety and damaging equipment.

How Noormsons Can Help

Noormsons is a trusted name in the bearings industry, offering a wide range of high-quality solutions tailored for industrial applications. Here’s how Noormsons can meet your needs:

1. Comprehensive Product Catalog

From ball bearings to specialized industrial solutions, Noormsons provides an extensive range of products. Explore their offerings here.

2. Expert Assistance

Their knowledgeable team provides personalized guidance, helping you select the most suitable bearings based on your specific requirements.

3. High-Quality Standards

Partnering with leading brands like NTN, Noormsons ensures durability, reliability, and exceptional performance.

4. Custom Solutions

Noormsons offers tailored options for unique industrial challenges, ensuring the best fit for your machinery.

5. After-Sales Support

Maintenance tips, troubleshooting, and replacement services are part of their commitment to customer satisfaction.

6. Cost-Effective Solutions

Their competitively priced products deliver outstanding value, reducing operational costs without compromising quality.

Best Practices for Bearing Maintenance

Proper maintenance ensures that bearings operate smoothly, minimizing the risk of failures. Follow these tips:

1. Regular Inspections

Check for signs of wear, misalignment, or contamination regularly.

2. Proper Lubrication

Use the recommended lubricant and ensure it is applied in the correct quantity.

3. Clean Environments

Protect bearings from dirt, moisture, and other contaminants.

4. Precision Installation

Use appropriate tools and follow manufacturer guidelines to install bearings correctly.

5. Monitor Performance

Employ monitoring systems to track bearing temperature and vibration levels for early fault detection.

Industries That Rely on High-Quality Bearings

Bearings are indispensable across various industries:

- Manufacturing: Used in conveyor belts, motors, and automated systems.

- Automotive: Essential for engines, gearboxes, and wheel assemblies.

- Construction: Heavy-duty bearings ensure the efficiency of cranes, bulldozers, and excavators.

- Energy: Wind turbines, power plants, and solar systems rely on bearings for smooth operations.

- Aerospace: Precision bearings are critical in aircraft engines and landing systems.

Why Quality Bearings Are Worth the Investment

Investing in high-quality bearings offers long-term benefits, such as:

- Enhanced Equipment Performance: Smooth operations reduce wear and energy consumption.

- Minimized Downtime: Durable bearings ensure uninterrupted production cycles.

- Lower Maintenance Costs: Reliable bearings decrease the need for frequent repairs.

- Increased Safety: Robust bearings prevent accidents and ensure worker safety.

Conclusion

The importance of choosing the right bearings for industrial equipment cannot be overstated. From improving efficiency to preventing costly failures, bearings are integral to the smooth operation of machinery. Considering factors like load capacity, speed, and environmental conditions ensures optimal bearing performance.

Noormsons stands out as a reliable partner in this domain, offering a diverse range of high-quality bearings, expert guidance, and unparalleled customer support. With their extensive catalog, competitive pricing, and commitment to excellence, Noormsons ensures your industrial equipment operates at peak efficiency.To discover their full range of products, visit Noormsons.

No comments