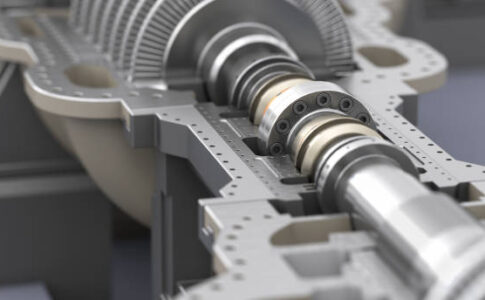

When it comes to construction projects, the reliability and efficiency of your machinery can make or break the job. At the heart of this machinery lies a crucial yet often overlooked component heavy duty bearings. Choosing the right bearings is essential to ensure maximum performance, reduce downtime, and extend the life of your construction equipment.

Why Heavy-Duty Bearings Matter for Construction Equipment

Construction machinery such as excavators, bulldozers, cranes, and loaders operate under extreme loads, tough terrains, and harsh weather conditions. These machines require components that can withstand constant heavy stress without failing.

This is where heavy duty bearings come into play. They are specifically designed to:

- Handle higher radial and axial loads

- Resist shocks and vibrations

- Operate smoothly even in dusty, muddy, or wet conditions

- Minimize wear and tear over time

By installing the right industrial bearing, you ensure that your construction equipment delivers consistent performance on even the toughest jobs.

How Heavy-Duty Bearings Improve Equipment Performance

1. Enhanced Load Carrying Capacity

Heavy-duty bearings are engineered with robust materials and advanced designs that allow them to carry heavier loads without distortion. Whether lifting tons of concrete or operating heavy drills, your equipment performs better when supported by bearings built for such pressure.

2. Improved Durability and Lifespan

Regular bearings may fail prematurely under construction site conditions. Heavy-duty bearings offer enhanced resistance to corrosion, abrasion, and contamination. This longevity means fewer replacements, lower maintenance costs, and higher uptime — a huge win for any construction business.

3. Smoother Operation and Reduced Friction

Friction is the enemy of machinery performance. Heavy-duty bearings are precision-engineered to minimize friction, leading to smoother operation, less heat generation, and better energy efficiency. This not only boosts performance but also helps save fuel and operational costs.

4. Greater Reliability in Harsh Environments

Construction equipment often operates in dusty, muddy, or wet environments. Heavy-duty bearings are sealed and shielded to prevent debris from entering, ensuring reliable performance even in the dirtiest conditions.

Choosing the Right Heavy-Duty Bearings

When selecting heavy duty bearings for your construction machinery, consider:

- Load ratings (both radial and axial)

- Operating speeds

- Environmental conditions (dust, moisture, temperature)

- Type of machine and specific application

At Noormsons, we offer a wide range of industrial bearings to match the unique needs of construction professionals. Our bearings are sourced from trusted brands and manufactured to the highest standards to ensure your equipment operates at peak performance.

Conclusion

If you want your construction equipment to last longer, perform better, and reduce operational costs, investing in high-quality heavy-duty bearings is a must. They might seem like a small part of the machine, but their impact on overall performance is massive.

No comments