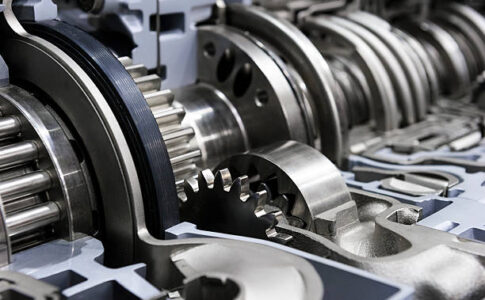

A ball bearing is a type of rolling-element bearing that uses balls to maintain separation between the bearing races. The purpose of a ball bearing is to reduce rotational friction while supporting both radial and axial loads. This is achieved by using smooth, hardened steel balls placed between two races — an inner and an outer ring.

The design allows the balls to rotate freely, reducing contact area and thus lowering friction. This makes ball bearings ideal for applications where smooth, high-speed rotation is needed.

Types of Ball Bearings

There are several different types of ball bearings, each designed for specific use cases. Here are some of the most commonly used types:

1. Deep Groove Ball Bearings

These are the most widely used ball bearings in the world. They can handle both radial and axial loads and are commonly found in electric motors, gearboxes, and household appliances. Their versatility and durability make them ideal for a range of applications.

2. Angular Contact Ball Bearings

Angular contact bearings are designed to carry high axial loads in one direction. They are commonly used in machine tool spindles and automotive applications where precise rotation and stability are critical.

3. Self-Aligning Ball Bearings

These bearings have two rows of balls and a spherical outer ring raceway, allowing them to self-align. They are perfect for applications where shaft misalignment may occur, such as in agricultural equipment or textile machines.

4. Thrust Ball Bearings

Used mainly in low-speed applications, thrust ball bearings are designed to carry axial loads only. They are typically used in automotive steering systems and vertical shafts.

Each type serves a unique purpose, and selecting the right bearing depends on load requirements, speed, alignment conditions, and the working environment.

Common Applications of Ball Bearings

Ball bearings are found in a wide range of machines and devices. Here are a few industries and systems that rely on them:

- Automotive: Wheel hubs, engines, transmissions, and alternators.

- Industrial Machinery: Conveyor systems, motors, gearboxes, and pumps.

- Home Appliances: Washing machines, ceiling fans, and air conditioners.

- Medical Devices: Dental drills and imaging equipment.

- Aerospace: Jet engines and flight control systems.

- Robotics and Automation: Joints, wheels, and rotating arms.

In all these applications, the primary function of ball bearings is to support motion, reduce wear, and enhance the efficiency of mechanical systems.

Why Quality Matters in Ball Bearings

When it comes to ball bearings, quality makes a significant difference. Cheap or low-grade bearings may cost less initially, but they often fail prematurely — leading to machine downtime, costly repairs, and even safety risks.

High-quality ball bearings offer:

- Better load-handling capacity

- Enhanced durability

- Higher speed capabilities

- Lower noise and vibration

- Improved operational efficiency

That’s why leading brands like NTN bearings are widely trusted across industries for their performance and reliability.

Maintenance Tips for Long-Lasting Performance

Proper care and regular maintenance are essential to get the best out of your ball bearings. Here are some tips:

- Use the Right Lubrication: Greasing or oiling the bearing reduces friction and prevents overheating. Choose a lubricant suited to your bearing type and application.

- Keep Bearings Clean: Contaminants like dust, water, or chemicals can damage bearing surfaces. Use protective seals or shields to prevent exposure.

- Avoid Overloading: Bearings have specific load ratings. Excessive load can cause deformation or premature failure. Always select the right bearing size and type for your application.

- Monitor Noise and Vibration: Unusual noises or vibrations are often signs of wear or misalignment. Regularly inspect bearings and replace them if needed.

- Proper Installation: Improper mounting techniques can damage bearings. Use appropriate tools and follow manufacturer guidelines during installation.

By following these practices, you can significantly extend the service life of your ball bearings and keep your equipment running without interruption.

Conclusion

Ball bearings may be small components, but their impact on the performance, safety, and efficiency of machinery is huge. From automotive engines to industrial machines, they play a vital role in reducing friction and ensuring smooth movement.

Understanding the different types of ball bearings, their uses, and how to maintain them properly can help businesses reduce downtime, improve productivity, and save operational costs. If you’re sourcing ball bearings for your equipment, always choose a trusted supplier and focus on quality above all.

No comments