In the world of mechanical engineering, thrust bearings play a crucial role in supporting axial loads and ensuring smooth motion in rotating systems. These specialized bearings are essential in applications ranging from automotive to heavy machinery. In this guide, we will explore the various types of thrust bearings, their uses, and the benefits they offer.

What Are Thrust Bearings?

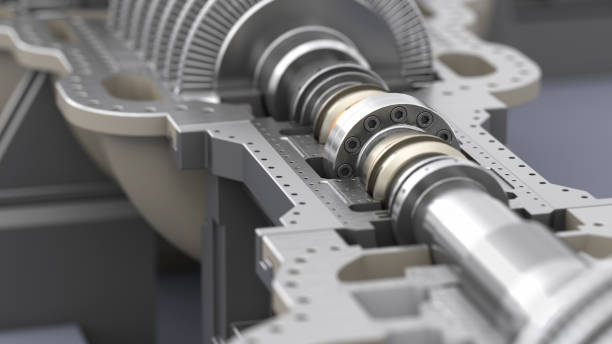

A thrust bearing is designed to handle axial loads, which are forces applied parallel to the bearing’s axis. Unlike radial bearings that manage perpendicular loads, thrust bearings support and control movement along a single direction, ensuring stability in rotating systems. They are commonly found in gear assemblies, pumps, and turbines.

Types of Thrust Bearings

1. Ball Thrust Bearings

These bearings consist of ball bearings placed between two washers. They are best suited for applications with lower axial loads and slower speeds, such as electric motors and automotive transmissions.

2. Roller Thrust Bearings

Roller thrust bearings use cylindrical rollers instead of balls, allowing them to handle higher loads. They are commonly used in heavy-duty machinery, including industrial presses and marine applications.

3. Fluid Thrust Bearings

These bearings utilize a thin film of fluid to reduce friction and support loads. They are ideal for high-speed applications like turbines and compressors, where minimal wear and tear are crucial.

4. Magnetic Thrust Bearings

Utilizing magnetic fields to provide support, these bearings offer a contact-free solution, reducing friction and improving longevity. They are commonly used in advanced aerospace and medical equipment.

Key Benefits of Thrust Bearings

1. Enhanced Load-Bearing Capacity

A well-designed thrust bearing effectively distributes axial loads, preventing excessive wear on machine components and increasing longevity.

2. Reduced Friction and Energy Loss

By minimizing resistance between moving parts, thrust bearings help reduce energy consumption and improve overall efficiency.

3. Improved Machine Durability

The use of high-quality thrust bearings, such as those available at Noormsons, ensures prolonged equipment life and lower maintenance costs.

4. Smooth and Reliable Performance

Machines operating with thrust bearings experience lower vibration levels, leading to quieter and more stable operation.

Choosing the Right Thrust Bearing

When selecting a thrust bearing, consider the following factors:

- Load Capacity: Ensure the bearing can handle the required axial force.

- Speed Rating: Choose a bearing suitable for the operating speed.

- Material and Lubrication: Opt for durable materials and proper lubrication to enhance performance and longevity.

Conclusion

Thrust bearings are essential components that enhance efficiency, durability, and performance in a wide range of industries. Understanding their types, uses, and benefits can help businesses make informed choices when selecting bearings for their applications. For premium-quality thrust bearings, check out Noormsons, where you’ll find reliable solutions for all your bearing needs.

No comments