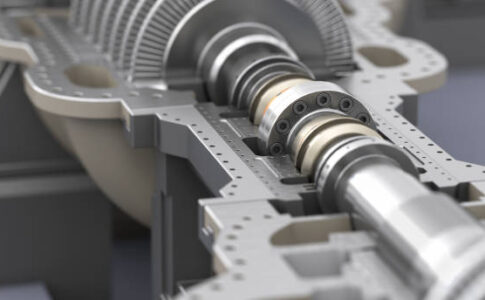

Machine tool spindles are the heart of any precision machining operation. These high-speed rotating components require reliable bearing solutions to ensure smooth performance, accuracy, and durability. Choosing the right machine tool spindles can significantly enhance efficiency, minimize downtime, and extend the lifespan of the equipment.

Role of Bearings in Machine Tool Spindles

Bearings play a crucial role in supporting the rotational movement of machine tool spindles. They help:

- Reduce friction for smoother operation

- Maintain precision and accuracy during machining

- Absorb loads and distribute them evenly

- Increase spindle life by preventing excessive wear and tear

A well-chosen bearing solution ensures that the spindle can operate at high speeds while maintaining optimal stability and precision.

Types of Bearings for Machine Tool Spindles

Several types of bearings are used in machine tool spindles, each offering unique advantages depending on the application.

1. Angular Contact Ball Bearings

- Designed for high-speed applications

- Handle both radial and axial loads efficiently

- Offer excellent precision and rigidity

2. Cylindrical Roller Bearings

- Ideal for handling high radial loads

- Provide enhanced stiffness and load-carrying capacity

- Commonly used in high-speed spindles

3. Tapered Roller Bearings

- Suitable for high-load applications

- Excellent shock load resistance

- Used in spindles requiring high rigidity

4. Hybrid Ceramic Bearings

- Feature ceramic rolling elements for reduced friction

- Operate at higher speeds with lower heat generation

- Longer service life compared to steel bearings

5. Hydrostatic and Hydrodynamic Bearings

- Utilize a thin film of fluid to reduce contact friction

- Provide near-zero wear for ultra-precision applications

- Used in specialized machining operations

Benefits of High-Performance Bearings for Machine Tool Spindles

Investing in high-quality solutions for machine tool spindles offers multiple advantages:

- Enhanced Precision: Bearings with high accuracy ensure smooth machining operations.

- Increased Speed: Optimized bearings support higher spindle speeds without overheating.

- Reduced Downtime: High-performance bearings last longer, reducing maintenance needs.

- Better Load Handling: Properly selected bearings distribute loads effectively, preventing premature wear.

- Lower Vibration & Noise: Advanced bearing technology minimizes vibrations for improved surface finish.

Factors to Consider When Choosing Bearings for Machine Tool Spindles

Selecting the right bearing depends on several key factors:

- Speed Requirements: Consider the spindle’s operating speed to choose a bearing that can handle high RPMs.

- Load Capacity: Determine the type and magnitude of radial and axial loads.

- Rigidity Needs: Ensure the bearing provides the necessary stiffness for precision machining.

- Lubrication & Cooling: Choose between grease or oil lubrication for optimal performance.

- Material & Durability: Hybrid ceramic bearings offer superior wear resistance over traditional steel bearings.

Conclusion

High-performance bearing solutions are essential for ensuring the efficiency, accuracy, and longevity of machine tool spindles. Choosing the right bearing type, maintaining proper lubrication, and conducting regular inspections can prevent downtime and enhance machining quality.

FAQs

1. What is the best type of bearing for high-speed spindles?

Angular contact ball bearings and hybrid ceramic bearings are ideal for high-speed spindles due to their low friction and high precision.

2. How often should machine tool spindle bearings be replaced?

The lifespan of spindle bearings depends on usage and maintenance. Regular monitoring and timely lubrication can extend their service life significantly.

3. What lubrication is best for spindle bearings?

Both grease and oil lubrication are used, depending on the application. Oil is preferred for high-speed spindles due to better heat dissipation.

4. How do I know if my spindle bearings are failing?

Signs of bearing failure include increased vibration, excessive noise, overheating, and reduced machining accuracy.

No comments