Bearings are essential components in mechanical systems, providing support and reducing friction between moving parts. Among the most commonly used types are ball bearings and thrust bearings. Each serves specific functions and is designed to handle distinct types of loads. In this article, we will explore the key differences between ball bearings and thrust bearings, their unique advantages, and how they are utilized across various industries. We’ll also highlight how Noormsons can be your trusted partner in sourcing high-quality bearings for your needs.

What Are Ball Bearings?

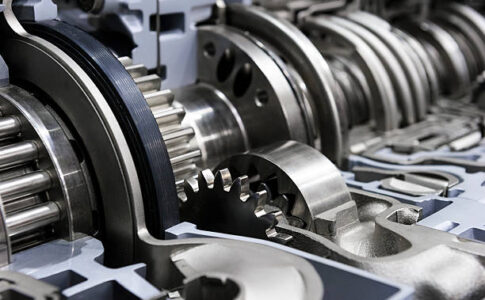

Ball bearings are the most widely used type of bearing, primarily designed to handle radial loads—forces perpendicular to the axis of rotation. They consist of a ring, an outer race, an inner race, and a set of steel balls that reduce friction and support the load. The balls roll between the races, ensuring smooth and efficient operation.

Key Features of Ball Bearings

- Versatility: Ball bearings can handle both radial and light axial (thrust) loads.

- Low Friction: The spherical shape of the balls minimizes contact area, resulting in reduced friction and heat generation.

- High Speed Capability: These bearings are ideal for applications requiring high rotational speeds.

- Compact Design: Ball bearings are compact and lightweight, making them suitable for space-constrained applications.

Applications of Ball Bearings

Ball bearings are used in a wide range of industries, including automotive, aerospace, medical devices, and consumer electronics. Common applications include electric motors, gearboxes, fans, and pumps.

What Are Thrust Bearings?

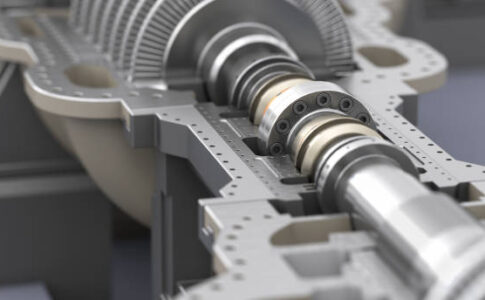

Thrust bearings, on the other hand, are designed specifically to handle axial loads—forces parallel to the axis of rotation. These bearings consist of a ring, rolling elements (typically balls or rollers), and a cage that keeps the rolling elements evenly spaced.

Key Features of Thrust Bearings

- Axial Load Handling: Thrust bearings are optimized for high axial loads, ensuring stability in applications where such forces dominate.

- Robust Construction: They are built to provide reliable performance under heavy loads.

- Low Rotational Speed: While effective for axial loads, thrust bearings are not designed for high-speed applications.

- Directional Load Support: They are typically unidirectional but can also be designed for bi-directional loads when required.

Applications of Thrust Bearings

Thrust bearings are commonly found in automotive transmissions, turntables, cranes, and machinery with rotating shafts that experience axial forces.

Comparing Ball Bearings and Thrust Bearings

1. Load Type

- Ball Bearings: Primarily handle radial loads but can accommodate light axial loads.

- Thrust Bearings: Specifically designed to support axial loads.

2. Speed Capability

- Ball Bearings: Ideal for high-speed applications due to their low friction and efficient rolling mechanism.

- Thrust Bearings: Operate at lower speeds, as they are designed for load stability rather than rotational speed.

3. Design and Construction

- Ball Bearings: Feature a simpler design with balls rolling between two races. Their compact size makes them versatile for various machinery.

- Thrust Bearings: Have a more robust construction to handle heavy axial loads, often resulting in a bulkier design.

4. Applications

- Ball Bearings: Used in high-speed machinery like fans, pumps, and electric motors.

- Thrust Bearings: Essential for equipment subject to axial loads, such as cranes, gearboxes, and automotive transmissions.

5. Cost and Maintenance

- Ball Bearings: Generally more cost-effective and easier to maintain due to their simple design.

- Thrust Bearings: Slightly more expensive, reflecting their specialized design and robust construction.

Choosing the Right Bearing for Your Needs

When selecting between ball bearings and thrust bearings, it’s important to consider the specific requirements of your application. Factors such as load type, speed, operating environment, and budget should guide your decision. Consulting with experts like Noormsons ensures you choose the right bearing for optimal performance and longevity.

How Noormsons Can Help

Noormsons is a trusted supplier of high-quality bearings, offering an extensive range of ball bearings, thrust bearings, and other precision components. Here’s why Noormsons is the ideal partner for all your bearing needs:

1. Comprehensive Product Range

Noormsons provides an extensive selection of bearings, catering to various industries and applications. Whether you require ball bearings for high-speed machinery or thrust bearings for heavy axial loads, Noormsons has the right product for your needs.

2. Expertise and Guidance

With decades of experience in the bearing industry, Noormsons offers expert advice to help you select the ideal bearing for your specific application. Their knowledgeable team ensures you get the best solution to optimize your machinery’s performance.

3. Quality Assurance

As a trusted supplier, Noormsons prioritizes quality, ensuring every bearing meets stringent industry standards. This commitment guarantees superior performance, durability, and reliability, reducing downtime and maintenance costs for your equipment.

4. Competitive Pricing

Noormsons combines premium quality with affordability. Their competitive pricing makes high-performance bearings accessible to businesses of all sizes, delivering excellent value for money.

5. Exceptional Customer Support

Customer satisfaction is at the heart of Noormsons’ operations. Their dedicated team provides ongoing support, from product selection to after-sales service, ensuring a seamless experience.

To explore the complete range of bearings and learn more about their benefits, visit the Noormsons product page.

Conclusion

Ball bearings and thrust bearings are both indispensable components in modern machinery, each serving unique purposes. Ball bearings excel in high-speed applications and handle radial loads effectively, while thrust bearings are designed for heavy axial loads in specialized equipment. Understanding their differences is crucial for selecting the right bearing for your specific needs.

With Noormsons as your trusted supplier, you gain access to an extensive range of high-quality bearings, expert guidance, and exceptional customer support. Whether you need ball bearings for high-speed machinery or thrust bearings for heavy-duty applications, Noormsons has the expertise and resources to meet your requirements.

Investing in the right bearings not only enhances machinery performance but also reduces maintenance costs and downtime. Contact Noormsons today to discover how their top-tier products and services can elevate your operations.

No comments